Tungsten Carter Strips Pemotong kanggo Woodworking

Katrangan

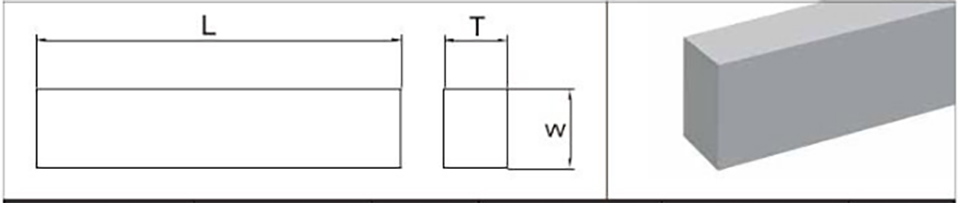

Bar flat carbide utamane digawe saka bubuk Wolfram Carbide lan Cobalt dening cara metallurgy bubuk. Proses produksi utama tungsten karboat bar saham bubur, panggilingan bal, panggilingan bal, terus nyinteran. Kanggo macem-macem panggunaan, isi WC lan CO ing Bar Carbide Carbide Square ora padha. Bar persegi solid biasane digunakake kanggo ngolah wesi cast abu-abu, bahan logam ora ferrous, bengkel, bahan bengkel, lsp.

Aplikasi

1. Digunakake kanggo nggawe alat tahan sing tahan. Kayata pisau industri kayu, living trus, lsp.

2 .. Digunakake kanggo nggawe bagean tahan suhu kanthi dhuwur, bagean tahan, bagean anti tameng. Kayata guduhan alur pandhuan mesin mesin, piring anti-nyolong mesin ATM, lsp.

3 .. Digunakake kanggo nggawe bagean tahan sing tahan ing industri karet lan plastik.

4. Digunakake kanggo nggawe cetakan.

5. Sifat-sifat material saka piring karpis kanggo tujuan sing beda-beda ora konsisten, lan bahan sing cocog karo piring karbida sing cocog kudu dipilih miturut panggunaan nalika nggunakake.

Spesifikasi

Ukuran umum kaya ing ngisor iki:

| Ketebalan | Jembaré | Dawane | Ketebalan | Jembaré | Dawane | ||||

| mm | mm Toleransi | mm | mm Toleransi | + 1.5mm Toleransi | mm | mm Toleransi | mm | mm Toleransi | + 1.5mm Toleransi |

| 2 | + 0,3 / 0.1 | 3 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 15 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 4 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 16 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 5 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 18 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 6 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 20 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 8 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 22 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 10 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 25 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 12 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 28 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 14 | + 0,4 / + 0.2 | 310 | 3 | + 0,3 / 0.1 | 31 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 15 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 5 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 16 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 6 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 18 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 8 | + 0,6 / + 0.2 | 310 |

| 2 | + 0,3 / 0.1 | 19 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 10 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 3 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 12 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 4 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 13 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 5 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 15 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 6 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 16 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 8 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 18 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 9 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 20 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 10 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 22 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 11 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 25 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 12 | + 0,4 / + 0.2 | 310 | 4 | + 0,3 / 0.1 | 30 | + 0,6 / + 0.2 | 310 |

| 3 | + 0,3 / 0.1 | 13 | + 0,4 / + 0.2 | 310 | |||||

Keuntungan

Kauntungan Strip tungsten Carbide kita:

1 .. stabilitas panas sing unggul.

2. Anti-deformasi ing suhu sing dhuwur.

3 .. resistensi kejut termal sing apik.

4. Konduktivitas termal dhuwur.

5. Kemampuan kontrol oksidasi sing apik.

6. Anti-Korosi sing kuat ing suhu sing dhuwur.

7. Rintangan karat sing apik saka kimia.

8. Fitur dhuwur nganggo.

9 .. umur sing dawa.

Paket

Paket Bar Carbide Sempet:

Yen sampeyan duwe pitakon, sambutan hubungi kita ing kapan wae!

Peralatan Produksi

Panggang udan

Pangatusan Semprotan

Penet

TPA Pencet

Semi-pencet

Sinter Hip

Peralatan Pengolahan

Pengeboran

Motong Kawat

Grinding vertikal

Grinding Universal

Plane Grinding

Mesin Penggilingan CNC

Instrumen inspeksi

Hardness meter

Planimeter

Pangukuran Unsur Quadratic

Instrumen Magnetik Kobalt

Mikroskop metalologis